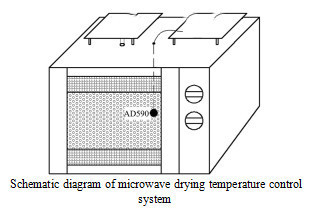

In this study, fresh Macadamia green peel was used as control group to study the effects of hot air drying at 60 ~C, microwave drying equipment and vacuum freeze drying on total phenols and flavonoids extraction and antioxidant activity of Macadamia green peel.

The results showed that compared with the control group, different drying treatments had effects on the total phenol, total flavonoids and antioxidant activity of Macadamia green peel. Vacuum freeze-drying treatment had the least effect on them. The total phenol and total flavonoids were 935.61 and 995.75 mg/hg, respectively. The half scavenging rates of DPPH radical and ABTS radical IC50 were 6.83 and 63.84 mg/L, respectively, and the total antioxidant capacity was about 6.83 and 63.84 mg/L. It was 1.74 times as much as Trolox, and there were significant differences in total phenols, total flavonoids and antioxidant activity of Macadamia green peel after different drying treatments (p < 0.05).