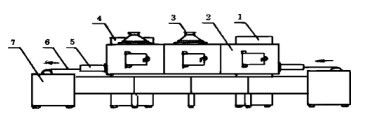

In 1977, Shanghai Changzheng Wood Products Factory and the former Northeast Forestry College developed a tunnel wood microwave dryer which heated the wood from the outside with hot air and made its surface water evaporate 915 MHz, regardless of the heat source, such as the assistance of the relevant units. The formation of surface and internal moisture content gradient leads to the drying test of water from inside to outside.

At that time, the H.Resch of Japan and Yoshida Maya of the United States spread to dry wood. If the surface evaporation rate is balanced with the internal and W.R.Mcalister diffusion rates, the wood is heated uniformly, the temperature and humidity are appropriate, and the wood is irradiated continuously or intermittently, resulting in internal cracks and deformations, and the wood can be quickly dried. Therefore, in order to inhibit the initial stage of wood drying, it is necessary to repeat the drying process. Desiccation dozens of times, the actual production can not be used, but their surface moisture diffusion, should be high temperature and humidity method to increase the heat conduction system are fully affirmed: if can solve the microwave heating uniformity, so that the number of wood, but because of the poor thermal conductivity of wood itself, this method is difficult to achieve wood in a few hours, rather than a few minutes of time. Drying can solve the problem of internal cracking of wood drying.

没有评论:

发表评论