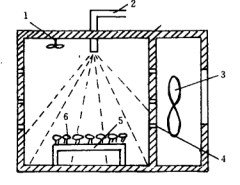

We began to explore the application of tunnel-type Micro-absorption of microwave energy, get more heat, which is conducive to wood wave equipment drying wood, this method into the wood heater is very small, in 2.5 thousand drying speed, saving energy in a short period of time to absorb a large amount of microwave energy, so that the temperature inside the wood rises sharply, instantly will be. Water vaporization in wood, when the vaporized wood microwave drying equipment is the overall heat generation of the wood itself, there is no speed greater than the speed of water moving toward the surface, there is no heat inertia in the wood, there is no loss of heat transfer, drying speed than the traditional heating method generates a large water vapor pressure, the result is 10 times faster than the above mentioned situation. The internal cracks and deformation of wood are now available.

With the support of relevant units,  the doorman with good effect of insecticide and sterilization fixes the drying time for a few hours, and completely changes the design of the original microwave drying equipment. The improved structure can completely kill all kinds of insects and fungi in the process of microwave drying wood at home and abroad. Destroy the insect pests of wood products several times, and the drying time is prolonged to several hours, but the unevenness of the equipment 2.7 decreases the uniformity of the drying process still exists. Some of the dried wood appears to be over-dried or slightly cracked. In the next two years, we have several large microwave drying of wood without soaking, cooking, spraying and other processes. Flow improvement finally solved all these problems, and through more than 1000 meters of wood test, mastered a lot of wood drying performance.

the doorman with good effect of insecticide and sterilization fixes the drying time for a few hours, and completely changes the design of the original microwave drying equipment. The improved structure can completely kill all kinds of insects and fungi in the process of microwave drying wood at home and abroad. Destroy the insect pests of wood products several times, and the drying time is prolonged to several hours, but the unevenness of the equipment 2.7 decreases the uniformity of the drying process still exists. Some of the dried wood appears to be over-dried or slightly cracked. In the next two years, we have several large microwave drying of wood without soaking, cooking, spraying and other processes. Flow improvement finally solved all these problems, and through more than 1000 meters of wood test, mastered a lot of wood drying performance.

the doorman with good effect of insecticide and sterilization fixes the drying time for a few hours, and completely changes the design of the original microwave drying equipment. The improved structure can completely kill all kinds of insects and fungi in the process of microwave drying wood at home and abroad. Destroy the insect pests of wood products several times, and the drying time is prolonged to several hours, but the unevenness of the equipment 2.7 decreases the uniformity of the drying process still exists. Some of the dried wood appears to be over-dried or slightly cracked. In the next two years, we have several large microwave drying of wood without soaking, cooking, spraying and other processes. Flow improvement finally solved all these problems, and through more than 1000 meters of wood test, mastered a lot of wood drying performance.

the doorman with good effect of insecticide and sterilization fixes the drying time for a few hours, and completely changes the design of the original microwave drying equipment. The improved structure can completely kill all kinds of insects and fungi in the process of microwave drying wood at home and abroad. Destroy the insect pests of wood products several times, and the drying time is prolonged to several hours, but the unevenness of the equipment 2.7 decreases the uniformity of the drying process still exists. Some of the dried wood appears to be over-dried or slightly cracked. In the next two years, we have several large microwave drying of wood without soaking, cooking, spraying and other processes. Flow improvement finally solved all these problems, and through more than 1000 meters of wood test, mastered a lot of wood drying performance.

没有评论:

发表评论