1 Introduction. In 30s, many countries began to study wood drying with high frequency. Since the 1960s, high frequency technology has made great progress in the research and application of wood-plastic composite and wood modification (1). China has achieved good results in high-frequency bonding technology. After the Second World War, the rise of microwave technology, the application of microwave drying wood, compared with high-frequency drying, there are many advantages, more attention. Microwave is the electromagnetic wave of 300MHx-300kM2. Theoretical and experimental points out that microwave drying is more advantageous than high-frequency drying because of high frequency.

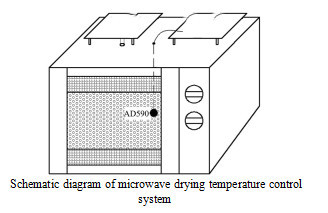

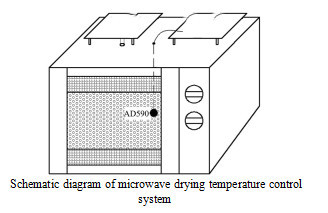

For example, the microwave dielectric loss thermal power density (heat per unit volume and time) can be increased by more than 20 times at the same field strength compared with the conventional microwave frequency of 915 MHz at 40.68 MHz. It also has the advantages of fast drying speed, small deformation, good quality, high utilization rate of heat energy, and is suitable for automatic production. The microwave drying technology of wood has been developed since 1974 in China. However, due to the stability of equipment, technological factors and economic problems, it is still in the stage of experimental production and scientific research. This paper attempts to discuss the mechanism of wood microwave drying, so as to make the workers in this field help and study together. Wood microwave drying machine Wood is a heterogeneous complex or composite dielectric composed of complex organic macromolecules and some inorganic substances

没有评论:

发表评论