According to the sectional density distribution curves of wood specimens in the initial state before drying, during drying and under dry condition, the sectional density distribution along the thickness direction can be obtained by linear interpolation and weighted average method.

In order to eliminate the influence of micro-machining defects on wood surface and the distortion of interface measurement data, the density data of 5 scan steps (thickness about 0.5 m) in the surface layer (the first and the 21st layers) were removed when calculating the average density.

The moisture content distribution in the direction of wood thickness was the most uneven before drying. With the drying process, the moisture content in each layer of wood decreased, and the decrease extent of inner layer was greater than that of surface layer. When the moisture content is below 10%, the moisture content distribution in the whole thickness direction is very uniform.

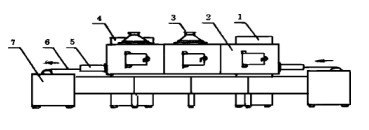

In the process of microwave drying equipment, the moisture content distribution in each layer of wood is inhomogeneous, that is, the moisture content of wood from the surface layer to the central layer does not always increase, but fluctuates. Even when the wood is dried to a very low moisture content (the average moisture content is about 5%), the moisture content in the inner part of the wood appears. Under the condition of lower than the surface layer, but the difference of moisture content is within 0.5%, and not all the inner layers are lower than the surface layer moisture content, so it can be considered that there is no integral moisture gradient of low and high moisture content inside the whole microwave drying process, that is, there is no moisture gradient field contrary to conventional drying.

没有评论:

发表评论