1 test materials and test methods

1.1 test materials

The tested rice was produced in the experimental farm of Guangzhou South China Agricultural University. The fresh rice was obtained from the newly harvested Taifeng indica rice containing stalks by hand threshing in laboratory and lifting wind to remove impurities. The rice was stored at 4 C for later test.

1.2 drying test device and test process

DHG 070B electric blast drying box was used to test hot air drying and moisture content of paddy. The temperature and velocity of hot air drying of paddy were 50 C and 50 C, respectively.

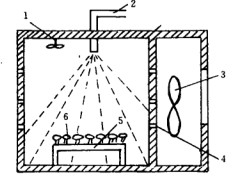

3.1 m/ s. The absolute dry temperature was 105 C and the drying time was 24 h. Microwave drying paddy was completed in a self-made P70F23P-G5 microwave device. The heating/cooling time of the device was 1 min/1 min and the drying power was 166W. The structure of the device was shown in Fig. 1.

The rice can rotate with the tray in the drying device when microwave drying. The quality components of fresh paddy and its samples during hot air and microwave drying were determined by Foss Infratec 1241 Analyzer near infrared fast grain analyzer (FOSS company of Denmark). The thermogravimetric loss and heat flux were measured by TG / DSC comprehensive thermal analyzer STA449. Germination rate of fresh rice and its samples dried by hot air and microwave was measured and counted in RXZ-280B intelligent artificial climate box.

没有评论:

发表评论