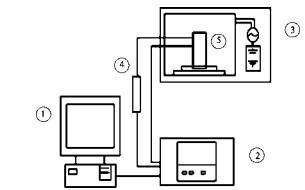

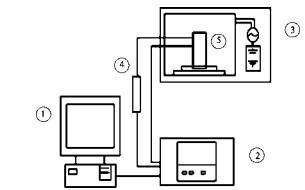

When drying, a small temperature probe was inserted into the material to control the temperature. The improved working principle is as follows: the microwave enters the furnace cavity through the waveguide tube, the agitator makes the microwave distribute uniformly, and the materials are heated uniformly; the wet air is discharged by the fan through the outlet hole (through the material wind speed is 0.3-0.4m/s), the mushroom variety L856, the initial moisture content is about 980%. After selection (for easy comparison, make it possible to make the wet air discharged by the fan). Each time drying size is similar, the shape is neat) to remove the pedicle, and then evenly spread on the insulating container network, the load is 6-6.5 kg/m2. In drying, every certain time, Fig. 1 microwave test box between the schematic diagram of perch structure quickly weighing, temperature measurement, until to reach a safe moisture content (13% wet stirrer 2. waveguide tube 3. fan base) after drying appearance quality using comprehensive addition. Right score method, and then please.Vitamin content was determined by 2,6-dichloroindophenol titration.

Table 1 Poetry Ordinance on Appearance Quality of Fragrant Mushroom (Full Score 40) Scoring Index Grade Weighted Value. Mushroom Cover Coloured with Yellow 4 Dark Yellow 2 Test results and Analysis Microwave Drying of Lentinus edodes Loss of Water Characteristics as shown in Fig. 2a. Constant Power Drying of Lentinus edodes Loss of Water Process can be divided into acceleration, constant speed and drop. The moisture band of Lentinus edodes is about 900%~280% in the constant speed period, and (b) the drying process of Lentinus edodes is only two stages of constant speed and slow down when the material weight is 0.5kg and the temperature of the mushroom pleat junction is controlled.

没有评论:

发表评论