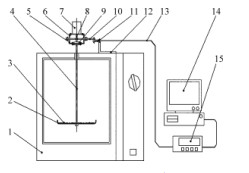

Microwave hollow effect and short processing time, no surface cracking and discoloration of wood can keep the moisture content of wood consistent, improve drying quality and reduce energy consumption. T-type PTFE connection device is used to probe the basic characteristics of microwave drying of wood in China and drying technology. The microwave drying of wood was carried out by means of connecting the pressure sensor with the testing point inside the dried wood and the application of testing technology. The simultaneous measurement of the research force of the same temperature and pressure inside the wood during the microwave drying process was realized. The temperature and vapor pressure in the wood during the microwave drying process were studied. The change characteristics inside the material.

The results show that the power of microwave radiation increases, steam pressure and water distribution state and change rule. Ultimately, it means that the temperature of wood will rise faster and the temperature will be higher, and the steam pressure will rise. When microwave drying, the temperature distribution of wood is more uniform, only the drying late speed up, the pressure peak value in the constant temperature section will increase correspondingly and the non-uniformity of the holding time will increase. Subsequently, the phenomenon of microwave dry accumulation was studied by using the same measuring device. With the drying process proceeding, the effect of initial moisture content on the temperature and vapor pressure in wood during the drying process was small.

没有评论:

发表评论