Microwave drying of wood may be used in the second stage of two-stage drying, that is, in the stage of low moisture content drying, which can give full play to its drying characteristics and reduce energy consumption appropriately. For example, dehumidification and microwave combined drying, air drying and microwave two-stage drying have the advantages of energy saving and rapid drying. The combined drying of these different methods is expected to have a better development prospects in the 21st century.

2 microwave moisture measurement

2 microwave moisture measurement

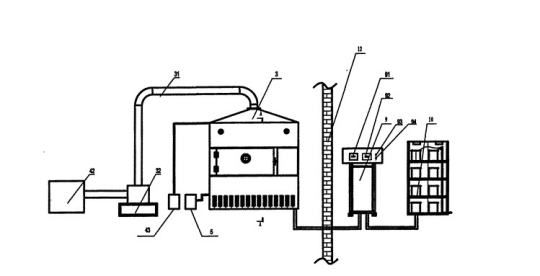

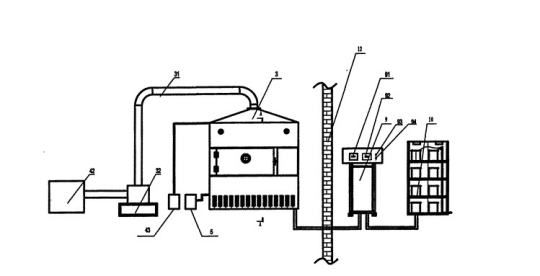

Microwave drying equipment

Microwave drying is usually done by microwave heating or dielectric constant measurement. The biggest advantage of microwave heating drying method is that it is fast and suitable for on-line determination, so it has important significance in water determination and on-line moisture measurement and control in production process. Another way to measure moisture by microwave technology is to measure the change of dielectric constant of material. In the microwave band, the dielectric constant of water is 50~81.

The dielectric constant of many other materials, such as plant fiber is 2.

4) much higher. So the dielectric constant of the material will have a great change if the moisture content changes slightly, so the moisture content of the material can be measured by measuring the dielectric constant change. Yin Xiaobing of Yunnan Academy of Forestry Sciences put forward the method of microwave oven-oven (WB-Oven) to measure the moisture content of Yunnan pine wood by microwave oven-oven method.

HX) method to improve the efficiency of determining wood moisture content. The method is divided into two steps to make the sample completely dry. The first step is to apply the principle of microwave drying to make the sample quickly dried in the microwave oven. The second step is to make the sample dried in the oven at constant temperature until it is completely dry. The total determination time of this method is 4-6 hours, which is 7 hours shorter than that of the conventional oven drying method, and the determination accuracy is in accordance with the national standard.

Microwave drying is usually done by microwave heating or dielectric constant measurement. The biggest advantage of microwave heating drying method is that it is fast and suitable for on-line determination, so it has important significance in water determination and on-line moisture measurement and control in production process. Another way to measure moisture by microwave technology is to measure the change of dielectric constant of material. In the microwave band, the dielectric constant of water is 50~81.

The dielectric constant of many other materials, such as plant fiber is 2.

4) much higher. So the dielectric constant of the material will have a great change if the moisture content changes slightly, so the moisture content of the material can be measured by measuring the dielectric constant change. Yin Xiaobing of Yunnan Academy of Forestry Sciences put forward the method of microwave oven-oven (WB-Oven) to measure the moisture content of Yunnan pine wood by microwave oven-oven method.

HX) method to improve the efficiency of determining wood moisture content. The method is divided into two steps to make the sample completely dry. The first step is to apply the principle of microwave drying to make the sample quickly dried in the microwave oven. The second step is to make the sample dried in the oven at constant temperature until it is completely dry. The total determination time of this method is 4-6 hours, which is 7 hours shorter than that of the conventional oven drying method, and the determination accuracy is in accordance with the national standard.

没有评论:

发表评论