The heat of conventional heating and drying is transmitted by conduction. From the surface to the inside, the direction of heat transfer is opposite to the direction of water evaporation, so the heating speed is slow and the efficiency is low. Natural drying takes months to years; hot air drying takes days to tens of days; and microwave drying is the overall heat generation of wood itself, without thermal inertia and heat transfer loss, drying only 10 minutes or tens of minutes, drying speed faster than traditional heating method.

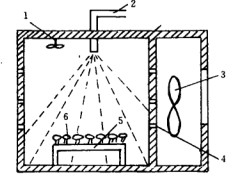

microwave drying equipment

Due to the permeability of microwave drying, moisture in wood is discharged from inside to outside simultaneously during the drying process, so that the expansion and shrinkage coefficient of wood is basically the same, the heating is uniform, the moisture content gradient of internal stress is small, which can avoid the deformation and cracking of wood in the drying process to the greatest extent. At the same time, the microwave drying process can completely kill all kinds of insects and fungi, eliminate wood pests, thus improving the drying quality of wood and wood products. In addition, the wood surface of microwave drying can keep its original color.

Due to the permeability of microwave drying, moisture in wood is discharged from inside to outside simultaneously during the drying process, so that the expansion and shrinkage coefficient of wood is basically the same, the heating is uniform, the moisture content gradient of internal stress is small, which can avoid the deformation and cracking of wood in the drying process to the greatest extent. At the same time, the microwave drying process can completely kill all kinds of insects and fungi, eliminate wood pests, thus improving the drying quality of wood and wood products. In addition, the wood surface of microwave drying can keep its original color.

Saving wood and increasing wood utilization

没有评论:

发表评论