Summary:

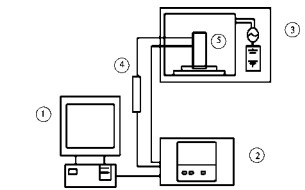

Objective: To investigate the changes of physical and chemical properties of galangal tablets before and after microwave drying equipment, and to determine the best quality and dryness. Methods: Colorimetry, UV spectrophotometer, high performance liquid chromatography, solid phase microextraction-gas chromatography-mass spectrometry were used to investigate the color, total phenolic content, total flavonoid content, galangal of six kinds of drying methods. The effect of the content of the element and the volatile component.

Objective: To investigate the changes of physical and chemical properties of galangal tablets before and after microwave drying equipment, and to determine the best quality and dryness. Methods: Colorimetry, UV spectrophotometer, high performance liquid chromatography, solid phase microextraction-gas chromatography-mass spectrometry were used to investigate the color, total phenolic content, total flavonoid content, galangal of six kinds of drying methods. The effect of the content of the element and the volatile component.

RESULTS: Freeze-drying had the largest comprehensive retention of total phenols, total flavonoids and galangin, total phenol (20.95±0.13) mg/g, total flavonoids (12.19±0.01) mg/g, galangin (11.45±0.03). ) mg/g, followed by vacuum heating and drying, hot air drying, microwave drying, sun drying, and natural air drying; the peak area of volatile substances after natural air drying and sun drying is lower, and the difference in peak area statistics of the other four drying methods is higher. Small; after microwave drying, the color is the deepest, the red and green value a* is 13.92, followed by hot air drying, and the freeze drying color is the lightest. Conclusion: Freeze drying can be used when high-end products are not considered for cost; solar energy drying is recommended when considering environmental protection and energy saving; traditional hot air drying is recommended for general industrial production.

没有评论:

发表评论