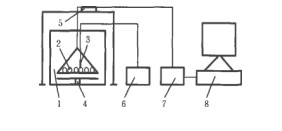

Abstract: In order to compare the common ingredients of hot air drying, vacuum freeze drying, traditional frying drying, vacuum drying, microwave drying equipment, temperature change, pressure drying and puffing drying, the nutrients, microstructure, sensory quality and flavor components of banana dry products. The impact of the production cycle. Physical and chemical analysis techniques were used to detect the content of nutrients; scanning electron microscopy was used to observe the microstructure; solid phase microextraction gas chromatography-mass spectrometry was used to analyze the flavor components; and the score method was used for sensory evaluation and comprehensive evaluation of coefficient of variation.

The results showed that the nutrient composition of banana products changed significantly under 6 different drying modes. The temperature-variation pressure difference puffing drying and vacuum freeze-drying could better preserve the various nutrients of the products. The scanning electron microscopy showed that the temperature and pressure difference puffed dry products had the largest cell gap, sensory The highest score was obtained. The results of solid-phase microextraction gas chromatography-mass spectrometry showed that banana products produced different kinds of flavor substances and unique flavor components in six different drying modes. The temperature change pressure difference puffing drying and vacuum freeze drying can better retain fresh An ester substance in bananas.

没有评论:

发表评论