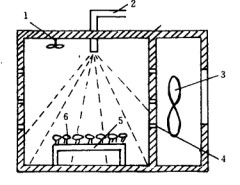

Microwave drying equipment is a kind of electromagnetic wave with frequency of (0.3-300) GHz, which has the characteristics of short oscillation period and strong penetration ability. Water molecule is polar molecule. Under the action of microwave, the water molecule in the material will polarize and arrange orderly along the direction of microwave electric field. Then it will rotate rapidly with the alternating change of high frequency alternating electric field direction, resulting in sharp friction and collision between the water molecule, so that the heat in the material is generated, and the water will leave the material. To dry purposes.

The effects of microwave drying conditions on spinach drying quality were investigated. The results showed that microwave drying of spinach could be divided into three stages: accelerated drying, constant drying and slowed-down drying, and the loss of water mainly occurred in the constant drying speed stage. With the increase of power, paving thickness and wind speed, the retention rate of VC decreases with the increase of paving thickness and increases with the increase of wind speed; the microwave drying power is 1.125 W/g, the paving thickness is 1.5 cm, and the wind speed is 75.

M/min is the best technology for microwave drying of spinach.

The spinach was dried under eight different microwave powers ranging from 90 W to 1000 W, and the drying time was reduced from 4005 s to 290 s. When the microwave power was between 350 W and 1000 W, the energy consumption was approximately the same; when the microwave power was between 750 W, the color and VC retention rate of spinach was the highest, and the energy consumption was relatively small, about 0.12 W.

KW.h.

没有评论:

发表评论