[Objective] To select the best drying method of sweet potato leaf powder, and to provide basis for enriching the varieties of sweet potato leaf products and prolonging shelf life.

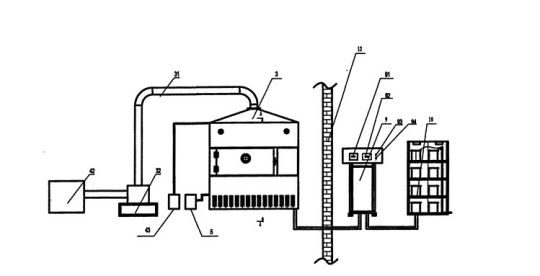

[Methods] sweet potato leaves were dried and pulverized by hot air drying equipment, microwave drying equipment, vacuum freeze-drying and spray drying. The effects of drying methods on the physical properties, microstructure and composition content of sweet potato leaf powder were studied, and the method of coefficient of variation weight was applied to the sweet potato leaves obtained by different drying methods. 4 methods were used to study the effects of drying methods on the physical properties, microstructure and content of sweet potato leaves. Comprehensive score of powder.

[results] the difference of color difference between vacuum freeze drying and spray drying sweet potato leaf powder was smaller, 3.98 and 3.86 respectively, showing better color; hot air dried sweet potato leaf powder had the highest bulk density of 0.76g / mL; spray drying sweet potato leaf powder had the lowest hygroscopicity, 10.05%; vacuum freezing. Dried and spray dried sweet potato leaves had smaller median diameter. The contents of total sugar and protein in spray dried sweet potato leaf powder were 218.71 and 27.85mg / g, respectively, which were significantly higher than those of other 3 drying methods (P < 0.05). The total phenol content and flavonoid content of vacuum freeze dried sweet potato leaf powder were the highest, 52.22 and 48 respectively. .46mg / G.

没有评论:

发表评论