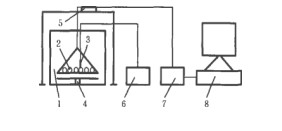

Abstract: In order to grasp the microwave drying law of sheet-like food materials and provide reference for production application, potato was selected as experimental material, and it was carried out under different microwave energy levels (2.2~3.6 W/g) and slice thickness (2-6 mm). Microwave drying experiments were carried out to determine changes in material temperature and moisture content during microwave drying.

Based on the heat balance equation and the diffusion equation, the corresponding model is established and solved by the finite difference method. The experimental results are basically consistent with the model calculation results.

The microwave drying equipment of sheet material undergoes three stages of preheating, constant temperature and rapid temperature rise: the material dehydration is less in the preheating stage; the material loses most of the water in the constant temperature stage, and the temperature increases as the slice thickness and the microwave power/mass ratio increase. In the rapid heating phase, the material drying rate decreases and its temperature rises rapidly. The drying rate is not affected by the change in the thickness of the material slice, but increases as the microwave power/mass ratio increases.

没有评论:

发表评论