ABSTRACT: The effects of microwave power, treatment time and slice thickness on pumpkin powder were studied, and their effects on pumpkin powder were compared.

The results showed that the stronger the microwave power was, the faster the water loss rate was, and the shorter the drying time was. The changes of microwave power and microwave treatment time had significant effects on the damage of pumpkin and carotene, while the thickness of pumpkin slices had no significant effect on the damage of pumpkin and carotene.

Pumpkin powder with good quality can be produced by using sliced pumpkin slices with thickness, microwave drying equipment of power and treatment time, and microwave drying method of grinding and sieving to produce pumpkin powder.

Keywords: microwave drying pumpkin powder

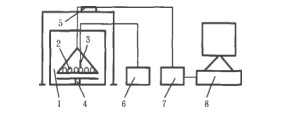

Pumpkin powder is a kind of safe and hygienic modern nutritional and health food because of its rich nutrition, medicinal value and health function. However, the hot air drying method used in pumpkin drying consumes a lot of power, and the loss of nutrients, such as carotene, is also more. Microwave drying mainly uses polar molecules in the medium to vibrate in the electromagnetic field to generate friction heat, and the field energy is transformed into heat energy, so as to achieve the purpose of drying.

没有评论:

发表评论